-

Shopping Bag Making Machines

-

Food Paper Bag Making Machine

-

Courier Bag Making Machine

-

Zipper Bag Making Machine

-

Diaper Bag Making Machine

-

Garbage Bag Making Machine

-

Heavy Duty Bag Making Machine

-

Liquid Bag Making Machine

-

Paper Slitting And Rewinding Machine

-

Paper Bag Handle Making Machine

-

Bag Sealing And Cutting Machine

-

Digital Bag Printing Machine

-

Bag Making Machine Parts

-

Plastic Bag Materials

-

Paper Bag Materials

Fully Automatic T Shirt Biodegradable Shopping Bags Making Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Weight | 3800 KG | Voltage | 380V/220V |

|---|---|---|---|

| Product Name | Biodegradable Shopping Bags Making Machine | Key Selling Points | Easy To Operate |

| Machine Type | Bag Forming Machine | Material | Non Woven Bag |

| Video Outgoing-inspection | Provided | Max Speed | 120pcs/min |

| Dimension(L*W*H) | 11500*1900*2100mm | Applicable Industries | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop |

| Highlight | T Shirt Shopping Bags Making Machine,Automatic Biodegradable Shopping Bags Making Machine,Fully Automatic biodegradable carry bag making machine |

||

2024 Latest Design Fully Automatic T-Shirt Biodegradable Shopping Bags Making Machine

Specification :

|

Material

|

Rolls of pp spunbond non woven fabric

|

If you have different requirements, please let us know, and we will provide you with customized solutions based on the actual

situation of the machine. |

|

Laminated non woven fabric

|

||

|

Production speed

|

60-80pcs/min

|

|

|

Fabric thickness

|

40-100gsm for bag body

|

|

|

60-100gsm for bag handle

|

||

|

Bag width

|

200-450mm

|

|

|

Bag height

|

300-700mm

|

|

|

Power supplier

|

220V/380V

|

|

|

Power

|

18kW

|

|

|

Overall dimension (L*W*H)

|

11500*1900*2100mm

|

|

|

Weight

|

3800kg

|

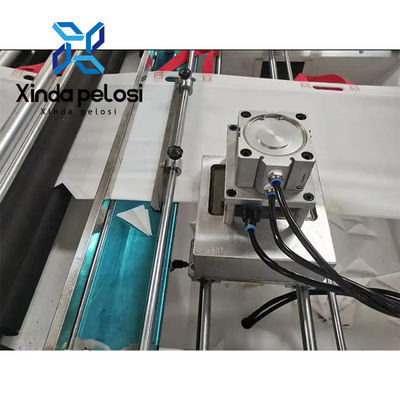

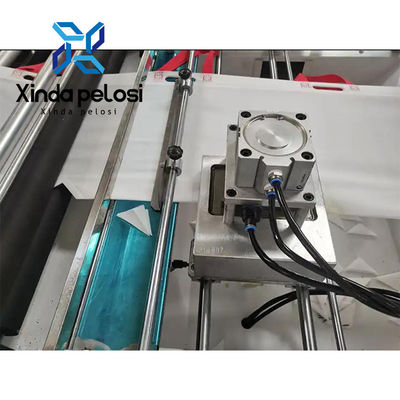

non woven rolls unwinding

Inflatable shaft to fix the fabric roll when machine working

Auto rectifying deviation system(EPC box and web guider)

Photocell eye for printing color mark tracking

Custom-made sealing mould is available

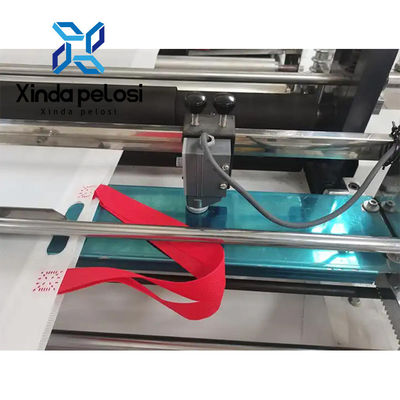

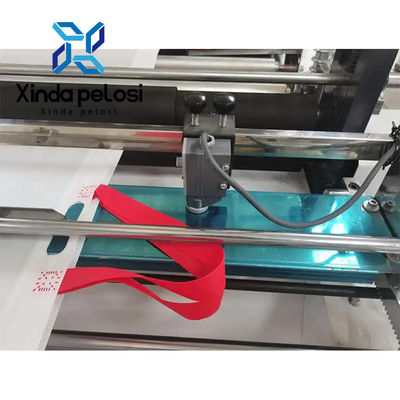

online handle attaching

Adjusted by touch screen

Man machine interface:touch screen

Motion control:PLC

non woven fabric feeding

non woven fabric cross folding

Manual web guider

bag gusset forming

T- shirt bag sealing by ultrasonic welding

bag sealing and cutting

Online D-cut punching, drawstring bag punching

Bag side sealing by ultrasonic welding system

static eliminator device

Man machine interface:touch screen

Motion control:PLC

FAQ :

1. How could we do after one year warranty period?

We also can do service for you, but you need pay salary for my technician 70USD/day.

2. How could we do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

3. Does your engineer understand English?

Our engineer understand a little English. All our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

4. Can you help us find any engineer in our location?

Of course, we will check and inform you as soon as possible.

5. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our sales at any time. Our engineer will take a solution video according your description.

6. How many worker do we need running those machines?

Except Two for bag making machine, flexo printing, slitting, ultrasonic sewing, hydraulic punching machine only need one person for each.

![]()