-

Shopping Bag Making Machines

-

Food Paper Bag Making Machine

-

Courier Bag Making Machine

-

Zipper Bag Making Machine

-

Diaper Bag Making Machine

-

Garbage Bag Making Machine

-

Heavy Duty Bag Making Machine

-

Liquid Bag Making Machine

-

Paper Slitting And Rewinding Machine

-

Paper Bag Handle Making Machine

-

Bag Sealing And Cutting Machine

-

Digital Bag Printing Machine

-

Bag Making Machine Parts

-

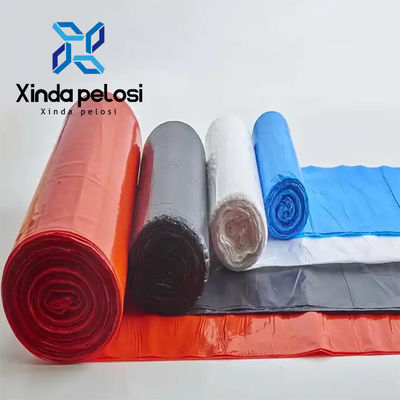

Plastic Bag Materials

-

Paper Bag Materials

Double Folding Biodegradable Garbage Bags Manufacturing Machine 150pcs/Min 380v

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Garbage Bag Manufacturing Machine | Machine Type | GARBAGE BAG |

|---|---|---|---|

| Max Speed | 150pcs/min | Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food Shop, Food & Beverage Shops, Other |

| Warranty | One Year | Dimension(L*W*H) | 3400mmX1200mmX1700mm |

| Bag Making Machine | Plastic Bag Making Machine | Weight | 1000 KG |

| Voltage | 380v | Key Selling Points | Automatic |

| Highlight | biodegradable garbage bags manufacturing machine 150pcs/min,150pcs/min garbage bag manufacturing machine,380v garbage bag manufacturing machine |

||

Bag Sealing Machine Of Roll And Double Folding Bag Making Machine Garbage Bag Manufacturing Machine

Product parameter:

|

item |

value |

|

Applicable Industries |

roll plastic bag |

|

Showroom Location |

None |

|

Condition |

New |

|

Machine Type |

BAG MAKING MACHINE |

|

Bag Type |

Garbage Bag |

|

Material |

Plastic |

|

Computerized |

Yes |

|

Place of Origin |

China |

|

|

Zhejiang |

|

Machine Type |

GARBAGE BAG |

|

Model Number |

XDP-500/600/700/800 |

|

Voltage |

380v |

|

Dimension(L*W*H) |

3400mmX1200mmX1700mm |

|

Weight |

1000KG |

|

Warranty |

1 year |

|

Key Selling Points |

Automatic |

|

Marketing Type |

Ordinary Product |

|

Machinery Test Report |

Provided |

|

Video outgoing-inspection |

Provided |

|

Warranty of core components |

1 Year |

|

Core Components |

Motor, PLC, Gear, Gearbox |

|

After-sales Service Provided |

Engineers available to service machinery overseas |

|

Warranty: |

1 year |

|

after sales service provided: |

Engineers available to service machinery overseas |

|

certification |

CE SGS |

|

bag making machine: |

Plastic bag making machine |

|

Bag making kind: |

Patch bag,String draw bag,Carry bag,Loop handle bag |

|

Computerized: |

Yes |

|

After Warranty Service |

Video technical support |

|

Local Service Location |

None |

|

Certification |

CE |

Garbage Bag Manufacturing Machines incorporate several advanced technologies to automate and optimize the production process of garbage bags. Here are some key technologies commonly found in these machines:

Material Handling Systems: These machines are equipped with advanced material handling systems to efficiently feed rolls of plastic film into the production line. This includes unwinding mechanisms, tension control systems, and material alignment devices to ensure smooth and consistent feeding of the plastic film.

Automatic Bag Forming: Garbage Bag Manufacturing Machines utilize automated bag forming mechanisms to fold, cut, and seal the plastic film to create individual garbage bags. These mechanisms are precision-engineered to produce bags of uniform size and shape with high accuracy.

Sealing Technologies: Various sealing technologies are employed to create strong and reliable seals on the garbage bags. Common sealing methods include heat sealing, ultrasonic sealing, or impulse sealing, depending on the type of plastic film used and the desired seal strength.

Control Systems: Advanced control systems regulate various parameters of the production process, including bag dimensions, sealing parameters, printing alignment, and machine speed. These control systems ensure precise control over the manufacturing process, resulting in consistent quality and optimal production efficiency.

Printing Units: Many Garbage Bag Manufacturing Machines are equipped with printing units to add graphics, logos, or text onto the garbage bags. Advanced printing technologies such as flexography or rotogravure printing ensure high-quality printing with accurate color reproduction and sharp detail.

Precision Cutting Mechanisms: Precision cutting mechanisms are utilized to accurately cut the plastic film to the desired bag size. These cutting mechanisms may include rotary knives, guillotine cutters, or laser cutting systems, depending on the specific requirements of the application.

Handle Attachment Systems: For garbage bags with handles, some machines feature handle attachment systems to automate the process of attaching handles to the bags during production. These systems ensure consistent handle placement and secure attachment to the bags.

Safety Features: Garbage Bag Manufacturing Machines are equipped with advanced safety features to protect operators and ensure safe operation. These may include emergency stop buttons, safety interlocks, light curtains, and protective guards around moving parts.

Energy Efficiency: Many modern machines are designed with energy-efficient features to minimize power consumption during operation. This includes the use of energy-efficient motors, variable frequency drives, and optimized heating elements.

Maintenance Monitoring Systems: Some machines are equipped with maintenance monitoring systems that track machine performance and alert operators to potential maintenance issues. This helps prevent unplanned downtime and ensures the machine operates at peak efficiency.

FQA:

1. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

2.what can you buy from us?

Film Blowing Machine,Plastic Bag Making Machine,Nonwoven Bag Making Machine,Printing Machine,Recycle Machine

3. why should you buy from us not from other suppliers?

We are engaged in producing Nonwoven bag making machine ,plastic bag making machine,Film blowing machine ,Printing machine,recycle machine and etc.Our machines running all over the world such as USD,Italy,England,India,Bengal,Dubai,Saudi Arabia,Ghana....

4. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

![]()

|

Garbage

|