-

Shopping Bag Making Machines

-

Food Paper Bag Making Machine

-

Courier Bag Making Machine

-

Zipper Bag Making Machine

-

Diaper Bag Making Machine

-

Garbage Bag Making Machine

-

Heavy Duty Bag Making Machine

-

Liquid Bag Making Machine

-

Paper Slitting And Rewinding Machine

-

Paper Bag Handle Making Machine

-

Bag Sealing And Cutting Machine

-

Digital Bag Printing Machine

-

Bag Making Machine Parts

-

Plastic Bag Materials

-

Paper Bag Materials

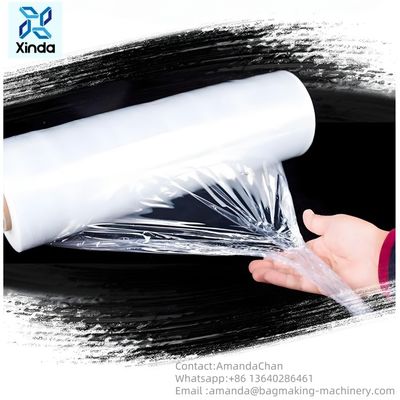

Customized PE Stretch Film Wrap Film Express Packaging Self-adhesive Plastic Film Industrial Pallets

| Place of Origin | Zhejiang |

|---|---|

| Brand Name | Xinda Pelosi |

| Certification | CE certification,RoHs,PSE,MSDS, etc. |

| Model Number | XDP-PEF |

| Minimum Order Quantity | 200roll |

| Price | To be negotiated |

| Packaging Details | 1 roll / Box By sea, by air, by courier |

| Delivery Time | 15days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 2000 Roll/Rolls per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | PE Stretch Film | Hardness | Soft |

|---|---|---|---|

| Application | Package | Color | Transparent |

| Feature | Dustproof/Moistureproof | MOQ | 200 Rolls |

| Industrial Use | Industrial Packaging | Thickness | 12mic-50mic |

| Advantage | Strong Toughness | Size | Custom Size Accepted |

| Highlight | Self Adhesive PE stretch film,Customized PE stretch film,Industrial Pallets PE stretch film |

||

Customized PE stretch film wrap film express packaging self-adhesive plastic film industrial pallets

Specification :

Item:Custom Film Roll Cellophane Wrapping ,Plastic Packaging Bags For Flower Custom Wrapping Cellophane

Material:PP, BOPP,CPP, PE

Feature:Moisture Proof/Security/Recyclable

Certificate:environmentally friendly material

Size/Color/logo:Customized

Processing type:Injection Molding

Thickness:Customized

Printing:Offset printing

MOQ:200roll

Overview

Our PE Stretch Film is engineered to deliver superior load stability and protection across diverse industries. Utilizing advanced polymer technology, this film combines exceptional elasticity, puncture resistance, and eco-friendly performance, making it a cost-effective choice for modern packaging needs.

![]()

![]()

Advanced Production Process

Our manufacturing process ensures consistency and high performance:

Material Blending: Premium PE resins are blended with specialized additives to enhance cling, UV resistance, and tear strength.

Multi-Layer Extrusion: State-of-the-art co-extrusion technology creates a multi-layered film structure, optimizing durability and stretchability.

Controlled Stretching: The film undergoes machine-direction orientation (MDO) to achieve up to 300% stretch capacity without compromising integrity.

Surface Treatment: Nano-coating technology is applied to improve static cling and dust resistance.

Precision Winding: Automated systems ensure uniform thickness (15–50 microns) and tension-free winding for smooth unwrapping.

Compliance Testing: Each roll is tested for elongation, load retention, and environmental safety (REACH/ROHS compliant).

Key Application Scenarios

Ideal for a wide range of industries:

Logistics & Shipping: Secures palletized goods (boxes, machinery, electronics) during long-distance transit.

Food & Beverage: FDA-approved films for bundling perishables, ensuring hygiene and moisture resistance.

Manufacturing: Protects raw materials and finished products from dust, scratches, and weather damage.

Agriculture: Stabilizes hay bales, silage, and greenhouse equipment with UV-stabilized variants.

Retail: Transparent, high-cling films for shelf-ready packaging and bundled consumer goods.