-

Shopping Bag Making Machines

-

Food Paper Bag Making Machine

-

Courier Bag Making Machine

-

Zipper Bag Making Machine

-

Diaper Bag Making Machine

-

Garbage Bag Making Machine

-

Heavy Duty Bag Making Machine

-

Liquid Bag Making Machine

-

Paper Slitting And Rewinding Machine

-

Paper Bag Handle Making Machine

-

Bag Sealing And Cutting Machine

-

Digital Bag Printing Machine

-

Bag Making Machine Parts

-

Plastic Bag Materials

-

Paper Bag Materials

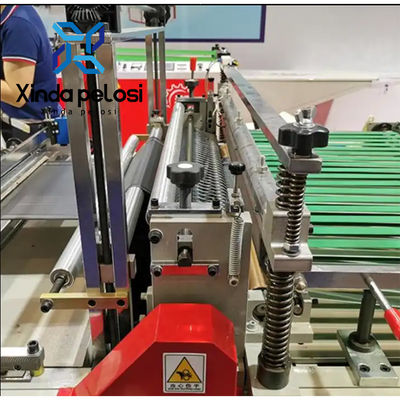

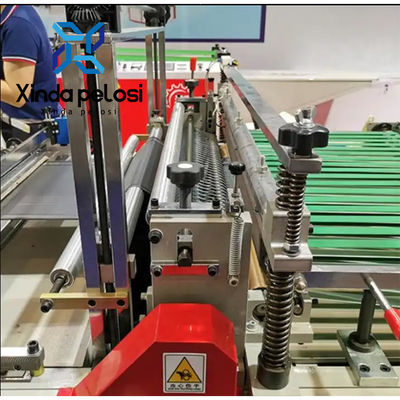

Double Lines Hot Cutting Polythene Shopping Bag Making Machines Middle Speed

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Shopper Making Machine | Machine Type | Shopping Bag |

|---|---|---|---|

| Material | Plastic | Video Outgoing-inspection | Provided |

| Max Speed | 400~460 Pcs/minute | Dimension(L*W*H) | 6000*1400*1600mm |

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory | Weight | 2000 KG |

| Voltage | 380V/220V 50HZ | Key Selling Points | Easy To Operate |

| Highlight | olythene Shopping Bag Making Machines,Shopping Bag Making Machines Middle Speed,Middle Speed shopping bag manufacturing machine |

||

Middle Speed Double Lines Hot Cutting Polythene Poly Nylon Shopper Making Machine

Specification :

| Applicable Industries | Plastic T-shirt Bag Making Busines |

| Weight | 2000 KG |

| Warranty | One Year |

| Warranty of core components | 5 years |

| Max Speed | 400~460 pcs/minute |

| Voltage | 380V/220V 50HZ |

| Dimension(L*W*H) | 6000*1400*1600mm |

| Place of Origin | Zhejiang, China |

Machine Introduction :

* Normal Speed: 200 ~230 cycle per minute *2 lines = 400 ~460 bags per minute

* To run with double lines per time, each line width 400 mm

Main Configuration:

1. Double unwinding stations

2. With soft sheets plus the photocells to control the back film feeding speed

3. Back film feeding controlled by two sets of AC inverter motors

4. Double printed mark track photocells so it can run with two lines even both lines with printed marks.

5. Hot sealing and hot cutting bar with fast high voltage heating

6. Automatic temperature controllers

7. Microcomputer control

8. Two servo motors working as feed-out

9. AC inverter motor used to drive the hot sealing and cutting bar

10. Automatic double lines handle puncher, which is automatic, but we have to move Halls position when bag length is changed.

11. Silicon cutting pad

Main Features

1. Computer control

2. Automatic bag size control

3. Automatic counter

4. Auto. stop if no film feeding

5. Auto. stop if missing printing mark

6. Auto. stop when pre-set bag quantity finished.

* Producing length :360-700 mm

* Producing speed for plastic bag: Max. 250 circle /min.*2 lines = 500 bags per minute

* Production speed for biodegradable bag: Max. 200 cycle/minute x 2 lines = 400 bags per minute

* Film thickness :0.010-0.035 mm

* Main motor:3 KW

* Air Pressure: 6kg/cm2; 700Ni/min

* diameter of unwinding roller: 800 mm

* Machine Weight: 2300 kg

* Overall dimension (L*W*H) 7000*1800*1900 mm

* Packing Size (L*W*H): 2150*1600*1550 mm and 2300*1510*2100 mm &1940*1480*1430 mm

FAQ :

Q1:How can I get more details of the machine?

>>Please click the "send" red below, and write down all your questions. And click send, we will reply you by mail in 24 hours.

Q2: What certificate do you have?

>>We have ISO9001, CE, the utility model patent certificate.

Q3:What is terms of payment? MOQ?

>> T/T. 1 Set.

Q4: What's the main market of your company?

>> We have customers all over the world.

Q5:How is your After-Sales Service?

>>One Year. And after-service team of high efficient, professional and enough experience.

Q6.What about the service after sale?

>>One you have bought our machine, you can call us or email us telling us the machine problems and any questions about the

machines. We will reply to you with 24 hours and help you to slove the problem.

![]()