-

Shopping Bag Making Machines

-

Food Paper Bag Making Machine

-

Courier Bag Making Machine

-

Zipper Bag Making Machine

-

Diaper Bag Making Machine

-

Garbage Bag Making Machine

-

Heavy Duty Bag Making Machine

-

Liquid Bag Making Machine

-

Paper Slitting And Rewinding Machine

-

Paper Bag Handle Making Machine

-

Bag Sealing And Cutting Machine

-

Digital Bag Printing Machine

-

Bag Making Machine Parts

-

Plastic Bag Materials

-

Paper Bag Materials

Full Auto Two Lines Coreless Roll Plastic Garbage Bag Making Machine Low Noise

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Garbage Bag Making Machine | Machine Type | GARBAGE BAG |

|---|---|---|---|

| Material | Plastic | Video Outgoing-inspection | Provided |

| Max Speed | 100m/min, 360-400pcs/min, 80-100m/min | Dimension(L*W*H) | 4750*2100*1450mm |

| Applicable Industries | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop | Weight | 2200 KG |

| Voltage | 380V | Key Selling Points | Easy To Operate |

| Highlight | coreless roll plastic garbage bag making machine,two lines plastic garbage bag making machine,two lines biodegradable garbage bag making machine |

||

Market Popularity Full Automatic Two Lines Coreless Roll Garbage Bag Making Machine

Specification :

|

Model

|

BL720L2-AR

|

|

Voltage

|

220/380V

|

|

Total Power

|

9.5KW

|

|

Average Power

|

4KW

|

|

Film Width

|

180-500mm

|

|

Bag Length

|

80-1500mm

|

|

Line Speed

|

80-100m/min

|

|

Production Speed

|

360-400pcs/min

|

|

Machine Length

|

4750mm

|

|

Machine Width

|

2100mm

|

|

Machine Height

|

1450mm

|

|

Machine Weight

|

2200KG

|

Features :

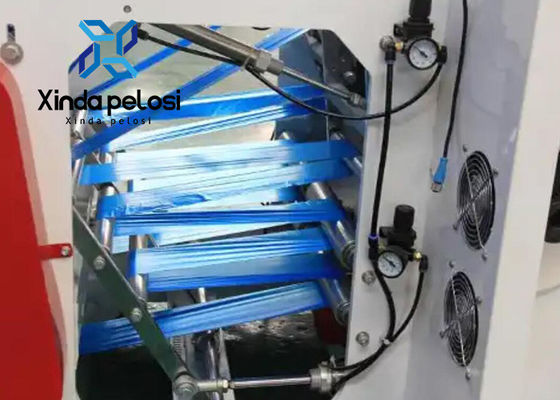

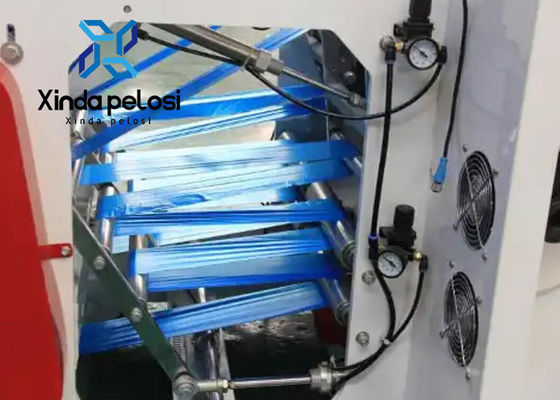

1. This bag making machine is applied to making perforation coreless rolling garbage bags or rubbish bags. And without paper-core star sealing bags or flat sealing bags.

2. Double bag film rolls with double functions unwinding structure.

3. Folding unit *2sets.

4. The machine adopts computer control system.

5. Automatic rewinder. This machine is equipped with automatic bag rolls rewinding and changing

6. With functions such as double bag film roll unwinding, folding system, photocell automatic tracking, strong heat-sealing device, microcomputer length setting, Taiwan Delta inverters, automatic counting, automatic alarm when reaching the set figure,

digital temperature controller, automatic bag rolls rewinding and changing.

7. It is an ideal fully automatic equipment to produce roll garbage bags, or for the bag plant to improve efficiency and reduce the labor demand device of choice.

Composition of plastic :

The plastic we usually use is not a pure substance, it is made up of many materials. Wherein polymer polymerization

Substance (or synthetic resin) is the main component of plastics, in addition, in order to improve the performance of plastics, but also to add in the polymer

Auxiliary materials, such as fillers, plasticizers, lubricants, stabilizers, colorants, etc., can become plastics with good performance.

1. Synthetic resin

Synthetic resin is the most important component of plastics, and its content in plastics is generally 40% to 100%. Due to the high content,

And the nature of the resin often determines the nature of the plastic, so people often regard the resin as a synonym for plastic. For example clustering

Vinyl chloride resin is confused with polyvinyl chloride plastic, and phenolic resin is confused with phenolic plastic. In fact, resin and plastic are two different

The concept. Resin is an unprocessed primitive polymer that is used not only in the manufacture of plastics, but also in coatings, adhesives, and coatings

Raw materials for synthetic fibers. In addition to a very small part of plastics containing 100% resin, the vast majority of plastics, except for the main group

In addition to the resin, other substances need to be added.

2. Packing

Fillers, also known as fillers, can improve the strength and heat resistance of plastics and reduce costs. For example, add phenolic resin

The addition of wood flour can greatly reduce the cost, making phenolic plastics one of the cheapest plastics, while also significantly improving mechanical strength.

Fillers can be divided into organic fillers and inorganic fillers, the former such as wood powder, rags, paper and various fabric fibers, the latter such as

Glass fiber, diatomaceous earth, asbestos, carbon black, etc.

3, plasticizer

Plasticizers can increase the plasticity and softness of plastics, reduce brittleness, and make plastics easy to process and form. Plasticizers are generally

High boiling point organic compounds that can be miscible with resins, non-toxic, odorless, stable to light and heat, the most commonly used are phthalates

Class. For example, when producing polyvinyl chloride plastics, if more plasticizers are added, soft polyvinyl chloride plastics can be obtained, if not added or

Add less plasticizer (dosage <10%), then hard polyvinyl chloride plastic.

4. Stabilizer

In order to prevent the synthetic resin from being decomposed and destroyed by light and heat during processing and use, it is necessary to extend the service life

Add a stabilizer to the plastic. Commonly used are stearate, epoxy resin and so on.

5. Coloring agent

Colorants can make plastics have a variety of bright, beautiful colors. Organic dyes and inorganic pigments are commonly used as colorants.

6. Lubricant

The role of the lubricant is to prevent the plastic from sticking to the metal mold during molding, and at the same time make the surface of the plastic smooth and beautiful.

Commonly used lubricants are stearic acid and its calcium magnesium salt.

In addition to the above additives, flame retardants, blowing agents, antistatic agents, etc., can also be added to the plastic to meet different needs

Please.

FAQ :

Q:Are you manufacturer?

A: Yes, We are manufacturer. We have factory, and design team, we design the machine according the customer product list.

Q:What can we provide for you ?

A: ERW Carbon Steel Tube Mills, Square & Rectangle Pipe Mill, Oil & Natural Gas Pipe Production Line, Slitting & Cut-to-length Line, Cold Roll Forming Mill, Steel Pipe Automatic Packing Machine, Related Machine. Finally we have more than 10 years Export experience.

Q:How to order the steel pipe making machine?

A: Please send us your purchase order by email, whatsapp or wechat. We need to know the following information for your order:

(1)Tube Mill Information: Pipe material (carbon steel or galvanized steel); Pipe Diameter, Pipe Thickness , monthly production etc.;

(2)Price Item, Destination Port, Delivery time required

(3)Shipping information: Company Name , Address, Phone Number , Destination Seaport/Airport

Q:What are the payment terms?

A:For orders, we can accept T/T, L/C at sight

Q:Whole Process for doing business with us ?

A:(1)Please provide details of the tube mill product you need we quote for you

(2)if you Require order, we will provide Performa invoice for you ,and we will arrange to produce at once when we get 30% deposit.

(3)We will send photos of all goods ,packing ,detail ,and B/L copy for you after goods are finished, we will arrange shipment and provide original B/L when you pay the balance.

![]()