-

Shopping Bag Making Machines

-

Food Paper Bag Making Machine

-

Courier Bag Making Machine

-

Zipper Bag Making Machine

-

Diaper Bag Making Machine

-

Garbage Bag Making Machine

-

Heavy Duty Bag Making Machine

-

Liquid Bag Making Machine

-

Paper Slitting And Rewinding Machine

-

Paper Bag Handle Making Machine

-

Bag Sealing And Cutting Machine

-

Digital Bag Printing Machine

-

Bag Making Machine Parts

-

Plastic Bag Materials

-

Paper Bag Materials

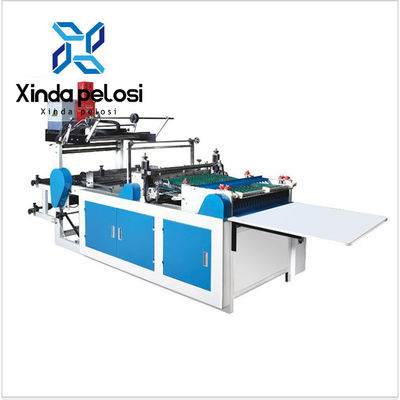

Different Color Plastic Express Bag Making Machine 220V/380V Fast Speed

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Plastic Courier Bag Making Machine | Machine Type | Ordinary Product |

|---|---|---|---|

| Bag Type | Courier Bag/ Dhl Bag | Max Speed | 200pcs/min |

| Dimension(L*W*H) | 3.6x1.1x1.7m | Machine Color | Can Be Different Color |

| Weight | 600kg | Warranty Of Core Components | 2 Year |

| Voltage | 220V/380V | Material | Plastic |

| Highlight | express bag making machine 220v,220v dhl bag making machine,fast speed dhl bag making machine |

||

Different Color, Plastic, Professional Express Plastic With Plastic Courier Bag Making Machine

Detail:

|

Model |

RDL-500 |

RDL-800 |

|

Max. Bag-making Width |

450mm |

750mm |

|

Max. Bag-making Length |

450mm |

750mm |

|

Max. Speed |

200pcs/min |

200pcs/min |

|

Main Motor Power |

1.5kw |

1.5kw |

|

Machine Weight |

700kg |

900kg |

|

Machine Dimension |

4.5x1.1x1.7m |

4.5x1.4x1.7m |

Character:

1. Pneumatic uploading material.

2. EPC device.

3. Inverter control.

4. Heat-sealing decorative border, automatic constant temperature, firm and smooth sealing.

![]()

![]()

Servo Motor System Conveyor

Yaskawa/Panasonic/Chinese Brand

![]()

![]()

Auto/Manual Tension/EPC System Upgraded Electric System

/Triangle Folding Device Omron Temperature

Yaskawa/Panasonic/Delta Inverter

Schneider Electric parts

The principle of a plastic courier bag making machine involves several key steps and components working together to efficiently manufacture plastic courier bags. Here's an overview of the principle:

Material Feeding: The machine begins by feeding rolls of raw material, typically polyethylene (PE) or polypropylene (PP) film, into the machine. These rolls serve as the primary material for manufacturing plastic courier bags.

Film Unwinding: The raw material rolls are unwound and fed into the machine using precision feeding mechanisms. This ensures a continuous supply of material for the manufacturing process.

Film Cutting: The machine accurately cuts the film into the desired width and length using precision cutting mechanisms. This step ensures uniformity in the size and shape of the courier bags.

Sealing and Welding: Heat sealing technology is employed to seal the edges of the film together, forming the sides and bottom of the plastic courier bags. High-frequency welding or ultrasonic welding may also be used for certain types of bags to ensure strong and durable seals.

Bag Forming: Once sealed, the machine folds and shapes the film to form the bags. Longitudinal folding creates the bag's sides and bottom, followed by transverse sealing to form the bag's closure. This step ensures precise folding and sealing to produce high-quality bags.

Handle Attachment (Optional): Some plastic courier bags may include handles for easy carrying. In such cases, the machine incorporates a handle attachment mechanism to add handles to the bags during the manufacturing process.

Printing (Optional): If required, the machine may include a printing station where logos, barcodes, shipping information, or other customizations can be printed directly onto the plastic courier bags as they are being produced.

Cutting and Stacking: Once the bags are formed and any printing or handle attachment is completed, they are cut from the continuous roll. Automatic stacking mechanisms ensure efficient handling and stacking of the finished bags for packaging or further processing.

Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that the plastic courier bags meet the desired specifications in terms of dimensions, seal strength, printing accuracy, and overall quality. This ensures that only high-quality bags are produced and delivered to customers.

Product Application:

This dhl courier bag making machine is suitable for hot-sealing and hot-cutting such materials as BOPP,OPP thermal contracting films.etc. And it is a kind of ideal equipment for making socks bag, towel bag, bread bag and ornament bag,etc. The photoelectric tracking stable performance(cast iron structure) and high speed etc. And has such functions as automatic gluing, automatic punching and lace heating-sealing, etc.

This machine has the functions: Servo motor (stepping motor) controlled by computer for feeding, infinite speed variation for machine running, photoelectric tracking for length, automatic gluing, automatic punching, and thermal edge sealing.

FQA:

1. Are you factory or trading company? Where is it?

We are factory located in Guangzhou City, Guangdong Province, China

2. What machines produced by your factory?

We are specialized in plastic machinery, such as film blowing machine, bag making machine, printing machine and plastic recycling machine etc.

3. What about installation and traning service?

We can train you at our own factory by free charge; or install/train at your factory and charge corresponding costs.

4. After-sale service?

Two year warranty. If any parts broken during this warranty period, we will send you new ones on the condition that you pay delivery cost.

Engineer's 24hr technical support.

![]()