-

Shopping Bag Making Machines

-

Food Paper Bag Making Machine

-

Courier Bag Making Machine

-

Zipper Bag Making Machine

-

Diaper Bag Making Machine

-

Garbage Bag Making Machine

-

Heavy Duty Bag Making Machine

-

Liquid Bag Making Machine

-

Paper Slitting And Rewinding Machine

-

Paper Bag Handle Making Machine

-

Bag Sealing And Cutting Machine

-

Digital Bag Printing Machine

-

Bag Making Machine Parts

-

Plastic Bag Materials

-

Paper Bag Materials

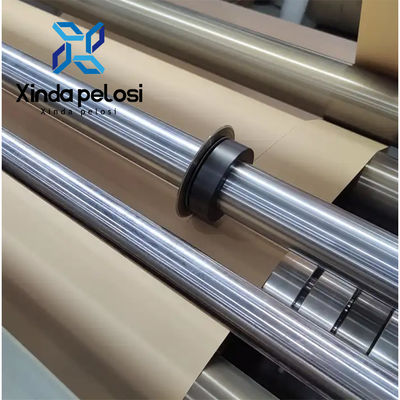

PLC Control 380V50HZ Thermal Paper Slitting And Rewinding Machine 8KW

| Place of Origin | Zhejiang |

|---|---|

| Brand Name | Xinda Pelosi |

| Certification | Machinery Test Report |

| Model Number | XP-SR |

| Minimum Order Quantity | 1 set |

| Price | To be negotiated |

| Packaging Details | Irregular Special Shaped Bag Liquid Sachet Filling Sealing Lotion Coffee Paste Maple Syrup Premade Pouch Packing Machine Packed By Wooden Box |

| Delivery Time | 45days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 50 Set/Sets per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Thermal Paper Slitting Rewinding Machine | Marketing Type | Ordinary Product |

|---|---|---|---|

| Dimension(L*W*H) | 1600*1500*1600mm | Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Printing Shops, Advertising Company |

| Machinery Test Report | Provided | Voltage | 380V50HZ |

| Color | Customized Color | Weight | 1300 Kg |

| Warranty | 1 Year | Power | 8KW |

| Highlight | paper slitting and rewinding machine 8kw,8kw paper slitter rewinder machine,plc control paper slitter rewinder machine |

||

Automic Thermal Paper Slitting Rewinding Machine Coreless Rewinding Cotton Tapes Slitting Machine

Product Paramenters

|

Item |

XDP-1300 |

|

Maximum material pay off width |

1300mm |

|

Main power |

8kw |

|

Speed |

0-150 meter /minute |

|

Slitting machine size |

2139mm*2500mm*1617mm |

|

Weight |

1300kg |

|

Pay off Diameter |

800mm |

|

Take up Diameter |

600mm |

|

Cutting accuracy |

0.05mm |

|

Power supply |

380v 50hz |

High productivity intelligent slitting machine, fast peed 300 meters/minute.

* This machine is a slitting machine with high precision and sensitivity

* The material is paid off and taken up by Hydraulic device.

* The tension is controlled by magnetic Powder Clutch, tension control and encoder.

* Intelligent, With PLC panel, touch screen,

* Fast speed, 150 meters in one minute.

* Vertical type, save space.

Applications:

Diffusion film,polyester, plastic film, radiation film, brightening film, black and white film, optical material, copper foil,

aluminum foil, PET, PC, PE, PP, OPP, PVC, non-woven fabric, non-woven fabric, conductive fabric, insulation paper, release paper,highland barley paper, fast bar paper, self-adhesive paper, Striping of materials such as paper tape, Mylar, reflective film, kraft paper, film, plastic, foam, etc.

Main features:

High productivity, fast peed 300 meters/minute.

The machine's wall panels and accessories are customized using CNC technology, ensuring the stability and cutting accuracy of the machine.

1. The entire machine is controlled by Mitsubishi PLC and Weilun touch screen, and the screen can set working parameters and display operating conditions.

2. The host adopts three imported frequency converters from Japan and servo motors for linkage control, with high speed and stable tension.

3. Adopting automatic hydraulic feeding, saving time and effort. The material can bear a weight of 2000KG.

4. Adopting a pneumatic pressure material receiving platform to save refueling time.

5. The machine adopts an automatic unloading system with a separate unloading arm.

6. Adopting an independent servo correction control system to correct material deviations.

7. The machine is equipped with an SMC proportional valve and a top solid pressure reducing valve, which can effectively adjust the tightness of the winding material during the automatic tension process of the slip shaft.

8. All transmission shafts are dynamically/statically balanced to ensure the stability and accuracy of material transmission and cutting processes. 9. Using a roller encoder automatic meter counting device, when the material is cut and rewind to the preset length, the machine will automatically stop working.

FQA :

1.What is a Thermal Paper Slitting Rewinding Machine?

A Thermal Paper Slitting Rewinding Machine is a specialized equipment used in the paper converting industry to cut large rolls of thermal paper into narrower widths and rewind them onto separate cores to create multiple smaller rolls.

2.How does a Thermal Paper Slitting Rewinding Machine work?

The machine unwinds a large roll of thermal paper, passes it through a slitting mechanism with sharp blades or knives to cut it into narrower widths, and rewinds the resulting slit rolls onto separate cores to create multiple smaller rolls suitable for thermal printing applications.

3.What types of paper can be processed with a Thermal Paper Slitting Rewinding Machine?

These machines are specifically designed for thermal paper, which is coated with a special heat-sensitive layer that reacts to heat to produce images. They can also process other types of paper used in thermal printing applications.

4.What are the key features of a Thermal Paper Slitting Rewinding Machine?

Key features include high precision slitting, adjustable slitting width, variable speed control, automatic tension control, safety features, compact design, material compatibility, ease of operation, low maintenance requirements, customization options, and integration capabilities.

5.What are the typical applications of a Thermal Paper Slitting Rewinding Machine?

These machines are used in various industries, including retail, banking, healthcare, logistics, and more, where thermal printing is used for receipts, labels, tickets, and other applications.

6.How can I ensure the quality of the slit rolls produced by the machine?

Regular maintenance, calibration of slitting blades, proper tension control, and monitoring of machine parameters are essential for ensuring the quality and consistency of the slit rolls produced.

7.What safety precautions should be followed when operating a Thermal Paper Slitting Rewinding Machine?

Operators should receive proper training on machine operation and safety procedures. Safety guards, emergency stop buttons, and interlock systems should be in place and regularly maintained to prevent accidents.

8.Can a Thermal Paper Slitting Rewinding Machine be customized for specific requirements?

Yes, many manufacturers offer customization options such as additional slitting stations, perforation units, edge guiding systems, and special features based on specific customer requirements.

9.Where can I purchase a Thermal Paper Slitting Rewinding Machine?

Thermal Paper Slitting Rewinding Machines are available from various manufacturers, distributors, and suppliers specializing in paper converting equipment. It's essential to choose a reputable supplier and ensure the machine meets your specific needs and requirements.

![]() ,

,