-

Shopping Bag Making Machines

-

Food Paper Bag Making Machine

-

Courier Bag Making Machine

-

Zipper Bag Making Machine

-

Diaper Bag Making Machine

-

Garbage Bag Making Machine

-

Heavy Duty Bag Making Machine

-

Liquid Bag Making Machine

-

Paper Slitting And Rewinding Machine

-

Paper Bag Handle Making Machine

-

Bag Sealing And Cutting Machine

-

Digital Bag Printing Machine

-

Bag Making Machine Parts

-

Plastic Bag Materials

-

Paper Bag Materials

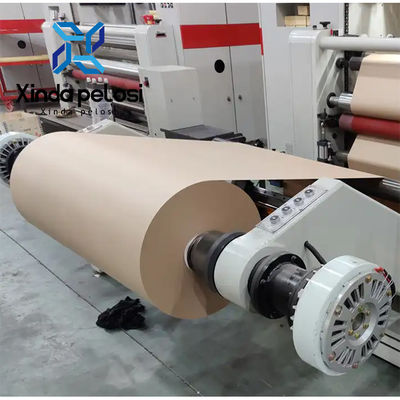

Fully Automatic Jumbo Paper Roll Slitting And Rewinding Machine 220V

| Place of Origin | Zhejiang |

|---|---|

| Brand Name | Xinda Pelosi |

| Certification | Machinery Test Report |

| Model Number | XP-SR |

| Minimum Order Quantity | 1 set |

| Price | To be negotiated |

| Packaging Details | Irregular Special Shaped Bag Liquid Sachet Filling Sealing Lotion Coffee Paste Maple Syrup Premade Pouch Packing Machine Packed By Wooden Box |

| Delivery Time | 45days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 50 Set/Sets per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Jumbo Paper Roll Slitting And Rewinding Machine | Power Supply | 220V 50/60Hz |

|---|---|---|---|

| Dimension(L*W*H) | 580*1660*370mm | Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Printing Shops, Energy & Mining, Advertising Company |

| Max. Workable Width | 1-1400mm | Voltage | 220V |

| Color | Customized Color | Weight | 173 Kg |

| Production Capacity | 30-120pcs/min | Usage | Paper Making Mill |

| Highlight | automatic jumbo paper roll slitting and rewinding machine,jumbo paper roll slitting and rewinding machine 220v,automatic paper roll slitting rewinding machine |

||

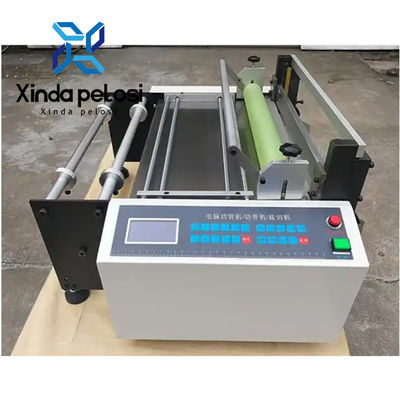

Fully Automatic Roll To Sheet Slitting Machine,Jumbo Paper Roll Slitting And Rewinding Machine

Product Paramenters

Product name | Jumbo Paper Roll Slitting And Rewinding Machine | |||

Product model | XDP-1400 | |||

Power supply | 220V 50/60Hz | |||

Cutting length(mm) | 0.1-99999.9mm | |||

Cutting speed | 30-120pcs/min | |||

Feeding width | 1-1400mm | |||

Cutting precision | 0.1mm | |||

Weight | 173kg | |||

Size (L*W*H) | 580*1660*370(mm) | |||

Feeding motor | Stepper motor | |||

Cutter motor | AC motor | |||

Cutter material | High-speed steel | |||

Features:

1,All kinds of film, cloth, paper and other roll materials can be cut.

2,The adjustable speed motor cooperates with the photoelectric sensor to realize automatic unwinding and synchronous cutting with

faster speed, higher efficiency and more accurate precision.

3,The machine is compact in design and smaller in size. It can be moved and installed at any time with all-in-one foot cup

casters.

4,The spring-type feeding mechanism is used with an angle-adjustable material receiving table, which can receive materials neatly

regardless of thickness and save labor.

5,Humanized design, simple operation, stable performance and easy maintenance

Product principle:

1. Automatic group accumulation and total cumulative count

2. Batch pause and delay time can be set

3. There are various manual operations for debugging

4. Can automatically cut all kinds of strips, sheets, plastic tubes and other materials

5. High-speed feeding, controlled by microcomputer program with an accuracy of 0.1mm

6. High-speed stepping motor accurately controls cutting length and speed

7. Cutting time protection; total setting; sub-setting; adjustable timeout

8. The cutter speed is adjustable, all Chinese LCD display, export or foreign companies can be customized English version

9. The length and speed are arbitrarily adjustable, fully automatic cutting and automatic feeding, completely liberating labor

10.LCD large screen intuitive Chinese display, simple and convenient operation; using special mechanical structure and special

tools,With special software control, it solves the problem of uneven cutting in other manufacturers, reaching the level of the

slit and the length

11. Fast feeding speed, high cutting force, high cutting efficiency, stable performance, cutting all kinds of hard and thick

materials, high cutting precision and straight cut

12. Add unwinding motor and induction photoelectric, which can realize synchronous unwinding, solve the problem of slow feeding

speed and poor precision of heavy coils.

Material Application

Suitable for cutting various PET protective films, reflective films, OPP films, PVC films, PE electrostatic films, ITO films,

plastic films, heat shrinkable films, hot melt adhesive films, thermoplastic films, thermal transfer films, release films,

non-woven fabrics, flocked fabrics, knitted fabrics, non-woven, abrasive gauze, leather, laundry pieces, self-adhesive paper,

insulating paper, release paper, highland barley paper, toilet paper, wrapping paper, roll paper, double-sided tape, copper foil,

aluminum foil, tin paper, EVA foam, pearl cotton and other roll materials.

FQA :

1.What is a Jumbo Paper Roll Slitting and Rewinding Machine?

A Jumbo Paper Roll Slitting and Rewinding Machine is a specialized equipment used in the paper converting industry to cut and rewind large jumbo rolls of paper into smaller widths and lengths.

2.How does a Jumbo Paper Roll Slitting and Rewinding Machine work?

The machine unwinds a large jumbo roll of paper, passes it through a slitting mechanism with sharp blades or knives to cut it into narrower widths, and rewinds the resulting slit rolls onto separate cores to create multiple smaller rolls.

3.What types of paper can be processed with a Jumbo Paper Roll Slitting and Rewinding Machine?

These machines can process various types of paper, including kraft paper, thermal paper, bond paper, and more, depending on the machine's specifications and capabilities.

![]() ,

,