-

Shopping Bag Making Machines

-

Food Paper Bag Making Machine

-

Courier Bag Making Machine

-

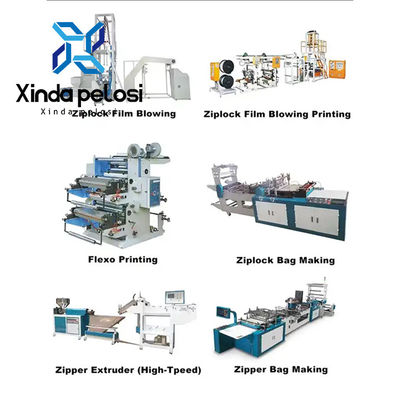

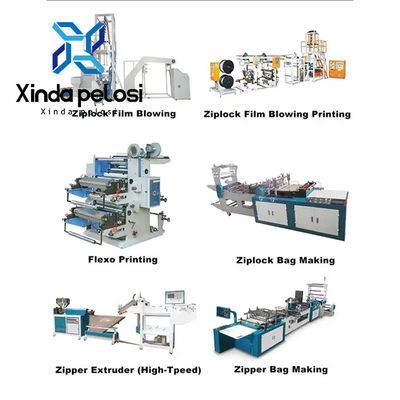

Zipper Bag Making Machine

-

Diaper Bag Making Machine

-

Garbage Bag Making Machine

-

Heavy Duty Bag Making Machine

-

Liquid Bag Making Machine

-

Paper Slitting And Rewinding Machine

-

Paper Bag Handle Making Machine

-

Bag Sealing And Cutting Machine

-

Digital Bag Printing Machine

-

Bag Making Machine Parts

-

Plastic Bag Materials

-

Paper Bag Materials

180pcs/Min Plastic Zipper Bag Making Machine 220V 50Hz Single Phase

| Place of Origin | Zhejiang |

|---|---|

| Brand Name | Xinda Pelosi |

| Certification | Machinery Test Report |

| Model Number | XPFD |

| Minimum Order Quantity | 1 set |

| Price | To be negotiated |

| Packaging Details | plastic ice cube bag making machine by flying knife system packing details:stretch film & bubble film wrapping onto wooden pallet shipment will be along with spare parts, instruction manual & components' manual. |

| Delivery Time | 70 days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 300 Set/Sets per Year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Machine Type | Zip Lock Pouch Packing Machine | Bag Type | Zipper Bag |

|---|---|---|---|

| Speed | 180pcs/min | Cutting Speed | 60-180pieces/min |

| Material | Plastic | Weight | 700 KG |

| Warranty Of Core Components | 1 Years | Applicable Industries | Restaurant, Machinery Repair Shops, Manufacturing Plant, Building Material Shops, Retail, Food Shop, Advertising Company, Garment Shops, Construction Works , Farms, Printing Shops, Hotels, Food & Beverage Factory, Home Use, Energy & Mining, Food & Beverage |

| Voltage | 220V 50Hz Single Phase | Dimension(L*W*H) | 3500*1500*1600mm |

| Highlight | zipper bag making machine 220v,180pcs/min zipper bag machine,180pcs/min zipper bag making machine |

||

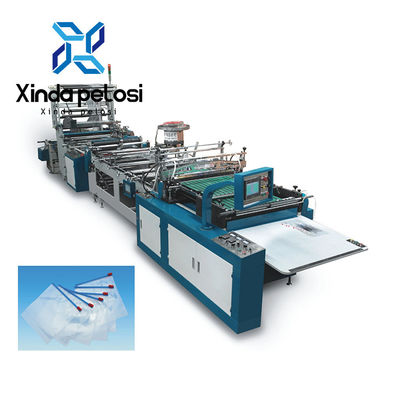

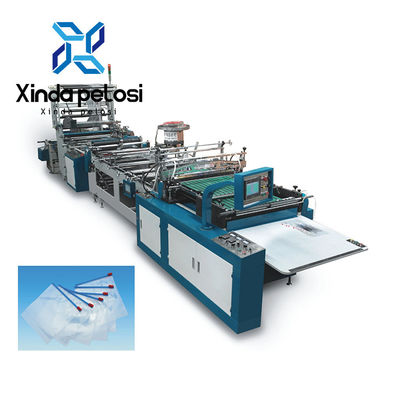

Automatic Various Widely Used Machine Zipper Plastic Bag Making Machine Zip Lock Pouch Packing

Product images :

| Main Technical Parameters | ||

| Model | ZIP-500 | ZIP-600 |

| Cutting width | 60-450mm | 40-550mm |

| Cutting length | 120-300mm | 40-420mm |

| Capacity | 60-180pcs/min | 60-180pcs/min |

| Main motor | 1.5kw | 1.5kw |

| Thickness of film | 0.04-0.15mm | 0.04-0.15mm |

| Heater | 15kw | 18kw |

| Power | 25kw | 30kw |

| Machine size | 3200*1100*1500mm | 3500*1500*1600mm |

Machine Description

This machine is apply to producing LDPE, PP, OPP, BOPP, or EVA zipper welding bags.

This machine adopts automatic servo motor driving and micro computer control the length. Which has the advantages of easy operation, strong sealing, good quality. The entire production process from the roll film, triangular folding, automatic edge lining, edge cutting, zipper welding, zipper head attaching, electric photocell tracking, punching, ultrasonic pressure level, to automatic counting are automatically controlled and operated by PLC control system.

Characteristics & Functions)

This machine is suitable for LDPE and non-woven fabrics. This machine adopts fully automatic servo motor and computer drive to control the length, easy operation, firm sealing and beautiful quality. The production process includes the entire film roll, automatic edge trimming, edge cutting, clip chain, laminating, automatic pull-in head, printing electric eye, punching, ultrasonic flattening, thermal cutting, automatic counting, and the whole process adopts PLC control system fully automatic operation.

Product technology:

Material Feeding: The machine feeds rolls of plastic film, typically made of polyethylene (PE) or polypropylene (PP), which serve as the primary material for pouch production.

Zipper Attachment: Specialized mechanisms attach the zipper to the plastic film, ensuring precise positioning and secure sealing to create the zip lock feature.

Filling System: Automated filling systems accurately dispense the desired product into the pouches, ensuring consistent fill levels and minimizing product waste.

Sealing Technology: Cutting-edge sealing technology, such as heat sealing or ultrasonic sealing, is utilized to seal the pouches, ensuring product freshness and preventing leaks.

Bag Forming: Bag forming mechanisms fold and shape the plastic film into the desired pouch shape, ensuring uniformity in pouch dimensions.

Optional Features: Some machines may include optional features such as printing units for branding or product information, gas flushing for modified atmosphere packaging (MAP), and date coding for traceability.

Control Systems: Advanced control systems, often utilizing PLC (Programmable Logic Controller) technology, regulate machine operations, ensuring precision and consistency in pouch production.

Safety Measures: Safety features such as emergency stop buttons, safety guards, and sensors are integrated to ensure operator safety during machine operation.

FQA :

A. What are products do you supply?

B. We are manufacturer of Plastic/Biodegradable film blowing machine,Bag making machine,printing machine,plastic recycling machine etc.

A.How about your products warranty ?

B.One year(12 months) Warranty will be provide from the date of container arrive Clients'factory.If machine parts are broken due to quality problem within warranty period, we will send new part for free( Any artificial misuse or destory prepensely is not included within the limitation of Quality Guarantee).

A.Why choose us?

B.(1) Efficient and satisfied service

(2) Complete machines solution for the whole production line

(3) Various and multi solutions for different requirement

(4) More than 18-year professional experience

(5) Qualified product and strict quality control

(6) ODM,OEM is welcome

![]()