-

Shopping Bag Making Machines

-

Food Paper Bag Making Machine

-

Courier Bag Making Machine

-

Zipper Bag Making Machine

-

Diaper Bag Making Machine

-

Garbage Bag Making Machine

-

Heavy Duty Bag Making Machine

-

Liquid Bag Making Machine

-

Paper Slitting And Rewinding Machine

-

Paper Bag Handle Making Machine

-

Bag Sealing And Cutting Machine

-

Digital Bag Printing Machine

-

Bag Making Machine Parts

-

Plastic Bag Materials

-

Paper Bag Materials

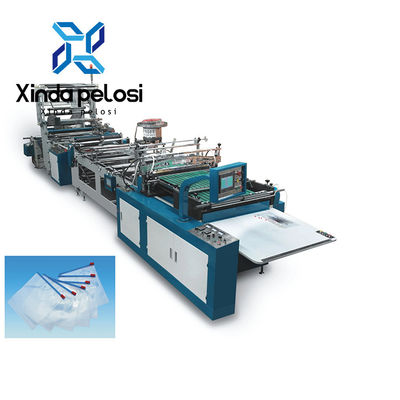

Horizontal Type PE Zipper Bag Making Machine With Auto Zipper Attaching System

| Place of Origin | Zhejiang |

|---|---|

| Brand Name | Xinda Pelosi |

| Certification | Machinery Test Report |

| Model Number | XPFD |

| Minimum Order Quantity | 1 set |

| Price | To be negotiated |

| Packaging Details | plastic ice cube bag making machine by flying knife system packing details:stretch film & bubble film wrapping onto wooden pallet shipment will be along with spare parts, instruction manual & components' manual. |

| Delivery Time | 70 days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 300 Set/Sets per Year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Machine Type | Zip Lock Making Machine | Bag Type | Zipper Bag |

|---|---|---|---|

| Applicable Industries | Garment Shops, Building Material Shops, Manufacturing Plant, Food & Beverage Factory, Home Use, Food Shop, Printing Shops, Construction Works , Food & Beverage Shops, Advertising Company | Max Speed | 40-80cycle/min |

| Material | Plastic | Weight | 1000 KG |

| Warranty Of Core Components | 1 Years | Key Selling Points | Easy To Operate |

| Voltage | 220V380V | Dimension(L*W*H) | 8500*1650*1800 |

| Highlight | pe zipper bag making machine,horizontal zipper bag machine,horizontal zipper bag making machine |

||

Horizontal Type PE Zipper Welding Bag,Zip Lock Making Machine With Auto Zipper Attaching System

Product images :

|

Model Number |

BCH-800 |

|

Voltage |

220V380V |

|

Raw Material |

LDPP-PE-PP-HDPE |

|

Bag Making Speed |

40-80cyclemin |

|

Bag Making Width |

100-600mm |

|

Bag Making Length |

100-650mm |

|

Film Thickness |

0.04-0.15mm |

|

Servo motor |

2kw |

|

Main motor |

1.5kw |

|

Heater |

3.8kw |

|

Discharge motor |

0.6kw |

|

Ultrasonic |

2kw |

|

Feeding motor |

0.75kw |

|

Fold the membrane motor |

0.55kw |

|

Cooling |

0.55kw,0.25kw |

|

Total Power |

15kw |

|

Dimension(L*W*H) |

8500*1650*1800 |

|

Voltage |

50hz,380v |

Main Technical

|

Model |

600 |

800 |

1000 |

|

Width of sealing&cutting |

700mm |

700mm |

700mm |

|

Length of sealing&cutting |

580mm |

780mm |

980mm |

|

Speed of bag-making |

40-240pc/min |

40-240pc/min |

40-240pc/min |

|

Power of motor |

3kw |

7kw |

10kw |

|

Weight |

700kg |

850kg |

950kg |

|

Outline dimension(LxWxH) |

3600x1200x1700mm |

3600x1400x1700mm |

3600x1600x1700mm |

Application:

This machine uses photoelectric track, computer control, frequency conversion velocity modulation and automatic temperature control, with the advantages of operating easily and sealing firmly. It is only used to seal and cut high pressure PE self-seal bags. It is an advanced bag making machine.

This machine can be widely used in the heat cutting plastic packaging products, such as self-seal bags, vest bags, gum sealing bags, woven bags, and so on.

FQA :

1.What is a zip lock making machine?

A zip lock making machine is specialized equipment used to produce zip lock bags, featuring a reclosable seal for easy opening and closing.

2.How does it work?

The machine processes rolls of plastic film, cutting, sealing, and forming them into bags with zip lock closures through precise mechanisms for zipper attachment, cutting, sealing, and bag forming.

3.What materials can it handle?

Zip lock making machines can work with various plastic films like polyethylene (PE) and polypropylene (PP), commonly used for packaging.

4.What are its benefits?

Benefits include increased production efficiency, reduced labor costs, consistency in bag quality and dimensions, customization options, and the ability to produce bags with convenient zip lock closures.

5.Is training required to operate it?

Yes, operators typically require training on machine operation, maintenance procedures, troubleshooting, and safety protocols.

6.What maintenance does it need?

Regular maintenance includes cleaning, lubrication, inspection of machine components, and replacement of worn parts to ensure smooth operation and prevent downtime.

7.Can it be customized?

Yes, many machines offer customization options for bag dimensions, material types, printing, handle attachment features, and more to meet specific requirements.

![]()